LKQ Inventory Edgewood provides a fascinating case study in automotive parts logistics. This analysis explores the intricacies of managing a large-scale inventory, from the physical layout of the Edgewood facility and its impact on part retrieval to the digital tools used to access and manage inventory data. We’ll examine the customer experience, pricing strategies, and the logistical challenges inherent in such an operation, offering insights into the efficiency and optimization of this crucial link in the automotive repair chain.

From understanding the types of inventory housed at the Edgewood location to navigating the online search system, this report provides a comprehensive overview. We will delve into effective search strategies, explore the use of filters and tools within the LKQ system, and examine key performance indicators (KPIs) used to measure inventory management efficiency. Furthermore, we’ll consider hypothetical scenarios, such as stockouts and customer service challenges, to illustrate real-world applications and potential solutions.

LKQ Inventory Edgewood: A Comprehensive Overview

LKQ Corporation, a leading provider of recycled auto parts, maintains a significant inventory at its Edgewood location. This article delves into various aspects of the LKQ Edgewood inventory, from its composition and accessibility to its management and customer impact. We will examine the logistical challenges, inventory optimization strategies, and customer experience associated with this large-scale operation.

Types of Inventory at LKQ Edgewood

The Edgewood LKQ facility typically stocks a wide range of recycled automotive parts, encompassing various makes, models, and years. This includes engines, transmissions, body panels, bumpers, headlights, taillights, and interior components. The inventory is categorized and organized for efficient retrieval. Specific part availability fluctuates based on incoming salvage vehicles and customer demand. The facility prioritizes parts in high demand, ensuring a ready supply for common repair needs.

Locating Specific Parts within LKQ Edgewood Inventory

Locating specific parts within the Edgewood LKQ inventory involves a multi-step process. Customers can utilize the LKQ online system, providing detailed vehicle information (year, make, model) and the desired part. The system cross-references this information with the available inventory at the Edgewood location. Alternatively, customers can contact the Edgewood facility directly, providing part numbers or descriptions. Experienced staff then use internal systems and physical location knowledge to pinpoint the part’s location within the yard.

Differences Between LKQ Edgewood and Other Locations

While all LKQ facilities share a similar inventory model, variations exist based on regional demand and the availability of salvage vehicles. The Edgewood location’s inventory might specialize in parts for specific vehicle types popular in its geographic area. The size of the inventory and the specific parts stocked will differ from other LKQ locations, influenced by local market trends and the volume of salvaged vehicles processed at each facility.

Pricing may also vary slightly depending on local market conditions and competition.

LKQ Edgewood Pricing Strategies

LKQ’s pricing strategy for parts in Edgewood is generally competitive, reflecting the condition of the part, its demand, and market rates. Pricing is dynamically adjusted based on several factors including supply and demand, part condition, and the age and model of the vehicle the part came from. Discounts may be available for bulk purchases or repeat customers. The pricing is transparent and usually displayed online or provided upon request.

Accessing and Utilizing LKQ Edgewood Inventory Data

Accessing and effectively utilizing LKQ Edgewood’s inventory data requires familiarity with their online system and efficient search strategies. This section provides guidance on navigating the system and optimizing searches for parts.

Searching for Parts within the LKQ Online System

Source: mktgcdn.com

- Access the LKQ website and navigate to the parts search function.

- Enter the required vehicle information (year, make, model, VIN if possible).

- Specify the desired part using either a part number, description, or .

- Select “Edgewood” as the location preference.

- Review the search results, noting part condition, price, and availability.

- Add selected parts to your cart and proceed to checkout.

Effective Search Strategies for LKQ Edgewood Inventory

Effective searches rely on accurate and detailed information. Using precise part numbers significantly improves results. If a part number is unavailable, using multiple s describing the part increases the chances of finding a match. Utilizing advanced search filters, such as part condition or price range, further refines the results.

Using Filters and Tools to Refine Searches

The LKQ online system offers various filters to refine searches. These filters include part condition (e.g., used, tested, new), price range, vehicle year, make, and model. Using these filters allows for a targeted search, reducing the time spent reviewing irrelevant results. The system also may offer visual aids such as images or diagrams of the part to ensure accuracy.

Hypothetical Mechanic Workflow Using LKQ Edgewood Inventory

| Step | Action | Expected Result | Potential Issue |

|---|---|---|---|

| 1 | Mechanic identifies needed part: driver-side headlight assembly for a 2012 Honda Civic. | Part number and description are identified. | Incorrect part identification. |

| 2 | Mechanic searches LKQ online system for the part, specifying Edgewood location. | List of matching parts with availability, condition, and price displayed. | No matching parts found in Edgewood. |

| 3 | Mechanic reviews search results and selects a suitable part. | Part selected, order placed, and confirmation received. | Selected part is unavailable. |

| 4 | Mechanic picks up the part at the Edgewood facility. | Part is retrieved, inspected, and deemed suitable. | Part is damaged or doesn’t match description. |

Inventory Management at LKQ Edgewood: Lkq Inventory Edgewood

Managing a large inventory like LKQ Edgewood’s presents significant logistical challenges. Efficient inventory management is crucial for profitability and customer satisfaction. This section explores these challenges and potential optimization strategies.

Logistical Challenges of Managing LKQ Edgewood’s Inventory

Challenges include space optimization within the facility, efficient part retrieval processes, accurate inventory tracking, and managing the flow of incoming and outgoing parts. Maintaining accurate records of part location and condition is crucial, as is effectively managing the constant influx of parts from salvaged vehicles. Seasonal demand fluctuations also impact inventory levels and management strategies.

Key Performance Indicators (KPIs) for LKQ Edgewood’s Inventory Management

KPIs used to assess efficiency include inventory turnover rate, order fulfillment rate, stockout rate, average inventory holding cost, and storage space utilization. Tracking these metrics allows for identification of areas for improvement and adjustments to inventory management strategies. Data analysis plays a crucial role in optimizing processes and minimizing costs.

Potential Inventory Optimization Strategy for LKQ Edgewood

Source: ytimg.com

An optimized strategy would involve implementing a robust inventory management system with real-time tracking capabilities. This system would integrate with the online search function, providing accurate availability information. Data analysis of historical sales data would inform purchasing decisions, minimizing overstocking and reducing the risk of stockouts. Regular inventory audits would ensure accuracy and identify potential issues early.

Resolving a Hypothetical Stockout Situation at LKQ Edgewood

A stockout of a high-demand part, such as a specific engine component, could trigger the following resolution steps:

- Identify the part and the extent of the shortage.

- Check for availability at other LKQ locations and initiate a transfer.

- Contact suppliers to expedite orders for new or used replacement parts.

- Communicate the stockout situation to affected customers, providing estimated delivery times.

- Analyze the cause of the stockout to prevent future occurrences.

Customer Experience with LKQ Edgewood Inventory

Understanding the typical customer profile and their experience is essential for improving service quality. This section explores the customer experience at LKQ Edgewood and identifies areas for enhancement.

Typical Customer Profile for LKQ Edgewood

Customers range from individual car owners performing DIY repairs to professional mechanics sourcing parts for their businesses. The customer base likely includes body shops, independent repair garages, and salvage yards. Customer needs vary based on their expertise and the urgency of their repair needs. Some customers might prioritize price, while others might prioritize part quality and availability.

Customer Service Procedures for Part Retrieval

Customers can retrieve parts either in person at the Edgewood facility or through delivery services. In-person retrieval involves presenting order confirmation and identification. Staff assists with locating and inspecting the part before purchase. Delivery options offer convenience but may incur additional charges. Customer service representatives address any inquiries or issues related to orders or part condition.

LKQ Inventory Edgewood’s extensive parts catalog recently saw a surge in demand for specific firearm components. This increase is partly attributed to the growing popularity of Adams Arms piston uppers, whose terms of use can be found here , impacting the availability of related parts at LKQ Edgewood. Consequently, LKQ Inventory Edgewood is adjusting its stock levels to meet this heightened consumer interest.

Comparing Customer Experience at LKQ Edgewood to Competitors

A comparison with competitors requires considering factors such as part availability, pricing, customer service responsiveness, and the ease of part retrieval. LKQ Edgewood aims to compete on price and part selection, while also providing efficient customer service. Competitor analysis might reveal opportunities for improving customer experience through enhanced online tools or improved communication.

Improving Customer Experience at LKQ Edgewood, Lkq inventory edgewood

- Enhance the online search functionality with improved filters and visual aids.

- Implement a more robust inventory management system for real-time availability updates.

- Provide clearer communication regarding order status and potential delays.

- Offer multiple convenient payment options.

- Train staff to provide friendly and helpful customer service.

Visual Representation of LKQ Edgewood Inventory

The physical layout of the Edgewood facility and the visual representation of inventory information significantly impact customer experience and operational efficiency. This section explores these aspects.

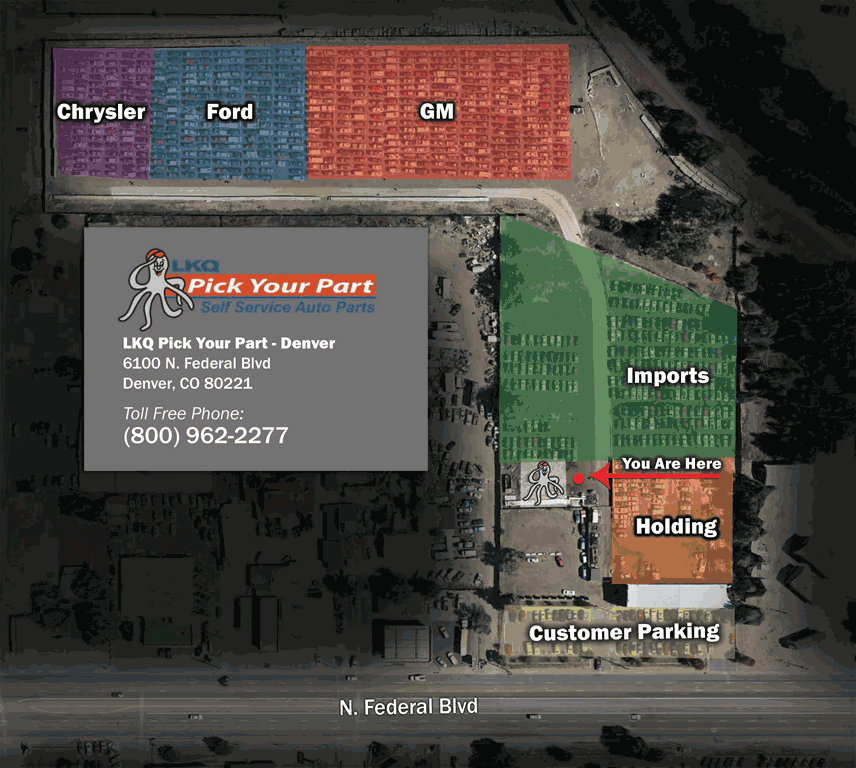

Physical Layout of LKQ Edgewood and its Impact on Inventory Organization

The LKQ Edgewood facility likely employs a system of organized rows and sections, categorizing parts by vehicle make, model, year, and part type. Incoming salvaged vehicles are processed, and parts are carefully removed, inspected, and cataloged. Parts are stored in designated areas, optimizing space and facilitating quick retrieval. The layout aims to minimize travel time for staff retrieving parts for customer orders.

Clear signage and organization are essential for efficient operation.

Visual Representation of Inventory Information within the LKQ System

The LKQ system likely includes detailed descriptions of each part, accompanied by high-quality images from multiple angles. These images help customers verify the part’s condition and suitability. Diagrams might illustrate the part’s location within a vehicle. For example, a hypothetical image showing the storage of headlights would depict rows of organized headlights, clearly labeled with vehicle make, model, and year.

Each headlight would have a unique identifier for tracking purposes.

Hypothetical Visual Aid: Part’s Journey from Arrival to Sale

A flowchart would illustrate this process. It would begin with the arrival of a salvaged vehicle, followed by its processing and part removal. The next step would involve part inspection and cataloging, leading to storage in a designated area. The flowchart would then show the part being identified in the online system, followed by a customer order, retrieval by staff, and finally, the sale and removal from the inventory.

Final Review

The LKQ Inventory Edgewood operation highlights the complex interplay between physical logistics, digital technology, and customer service in the automotive parts industry. Efficient inventory management, coupled with user-friendly online tools and responsive customer service, are key to success. Understanding the challenges and solutions presented in this analysis provides valuable insights for both LKQ and its competitors, shaping future strategies for optimizing inventory and enhancing the overall customer experience.